Decoration & Branding

There are many kinds of production processes for luggage logos, and different processes directly affect the texture, durability and visual effects of the logo. The following are common luggage logo production processes and their characteristics, which are suitable for different materials (such as leather, nylon, polyester, metal, etc.) and design requirements:

Hot Embossing

The logo is pressed into the surface of the material by heating the mold, and can be combined with metal foil (such as hot stamping, hot silver) or pigment.

– Applicable materials: Leather, PU, PVC, canvas, etc.

– Effect: The surface is flat, the color is bright, and the metal foil hot stamping has a glossy feel.

– Advantages: Low cost, high efficiency, suitable for mass production.

– Disadvantages: Easy to fade due to long-term friction, not suitable for complex patterns.

Cold Embossing

–No need to heat, directly form depressions or bulges on the surface of the material through pressure.

– Applicable materials: Thicker leather, hard synthetic materials.

– Effect: Strong three-dimensional sense, retaining the original texture of the material (such as leather embossing).

– Advantages: Natural retro, good durability.

– Disadvantages: There are requirements for material thickness and high process precision

Silk Screen Printing

The ink is leaked onto the surface of the material through the screen.

– Applicable materials: Textile fabrics such as canvas, nylon, polyester, etc.

– Effect: Rich colors, can print gradient or fine patterns.

– Advantages: Low cost, suitable for multi-color logos.

– Disadvantages: Poor wear resistance, easy to fall off due to friction.

Embroidery

Use an embroidery machine to sew the logo on the fabric with stitches.

– Applicable materials: Nylon, polyester, canvas and other textile bags.

– Effect: Strong three-dimensional sense, soft touch, commonly seen in brand logos.

– Advantages: Wear-resistant and washable, suitable for sports bags or outdoor bags.

– Disadvantages: Complex patterns are prone to roughness and high cost.

Metal Label

Metal stamping Use molds to stamp metal sheets (zinc alloy, stainless steel, etc.) to form a logo, and then fix it on the luggage.

– Applicable scenarios: Zipper heads, corners, handles, etc.

– Effect: Metallic luster, high-end texture.

– Advantages: Strong durability, not easy to wear.

– Disadvantages: High cost, increased weight.

Laser Engraving

Principle: Use laser to burn the surface of the material to form a logo.

– Applicable materials: leather, wood, metal, plastic.

– Effect: Clear lines, no color, but can express layers through changes in depth.

– Advantage: Permanent identification, environmentally friendly and pollution-free.

– Disadvantage: Only suitable for single color, dark materials require light-colored bottom layer treatment.

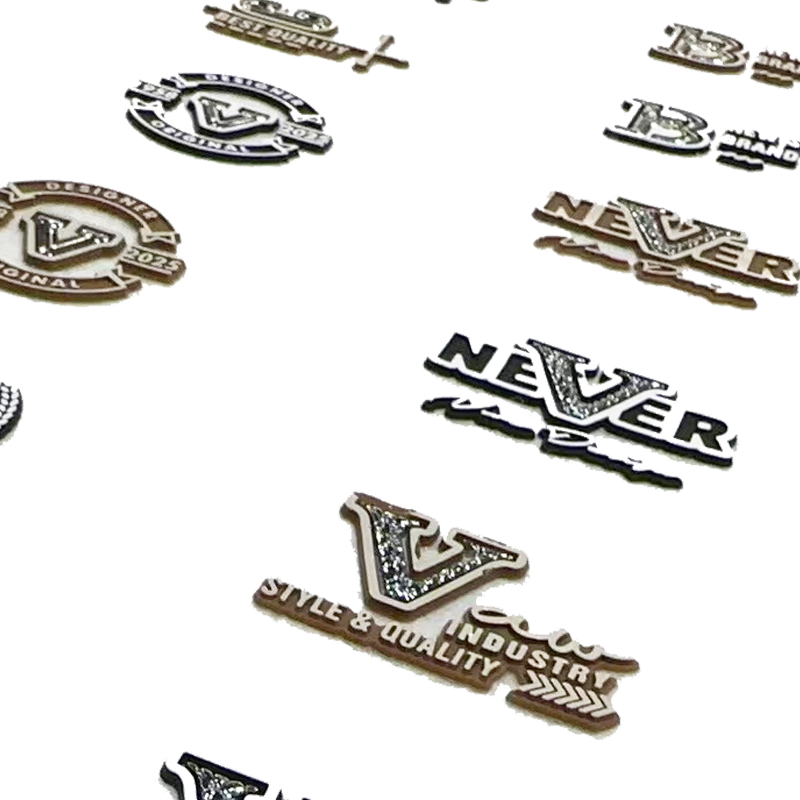

Glue Dripping

Principle: Drop transparent or colored resin on the logo area, and form a raised effect after curing.

– Applicable materials: leather, canvas, plastic.

– Effect: 3D stereoscopic effect, smooth surface like amber.

– Advantage: Visually eye-catching, wear-resistant and scratch-resistant.

– Disadvantage: Long process time, easy to deform at high temperature.

Silk Screen Printing

The ink is leaked onto the surface of the material through the screen.

– Applicable materials: Textile fabrics such as canvas, nylon, polyester, etc.

– Effect: Rich colors, can print gradient or fine patterns.

– Advantages: Low cost, suitable for multi-color logos.

– Disadvantages: Poor wear resistance, easy to fall off due to friction.

Hot Stamping/Hot Silver

Principle: Transfer metal foil to the material surface through heat pressing.

– Applicable materials: Leather, paper, textiles.

– Effect: Metallic luster, gorgeous and eye-catching.

– Advantages: Improve the grade, suitable for brand logo.

– Disadvantages: Easy to wear and fall off after long-term use.

3D Printing

Principle: Use resin or metal powder to stack layer by layer to form a three-dimensional logo.

– Applicable scenarios: High-end customized bags, conceptual design.

– Effect: Highly three-dimensional, can make hollow or complex structures.

– Advantage: High design freedom, no mold required.

– Disadvantage: Extremely high cost, difficult to mass produce.

Water Transfer

Principle: Print the pattern on the water transfer film, and then transfer the pattern to the material surface through water pressure.

– Applicable materials: Curved or special-shaped parts (such as luggage pull rods, metal accessories).

– Effect: Can cover complex shapes, and the pattern is seamlessly connected.

Advantages: Suitable for personalized customization.

– Disadvantages: Average durability, requires surface coating protection

Digital Direct Printing

Use UV ink to print directly and cure by ultraviolet light.

– Applicable materials: Leather, metal, plastic, textiles.

– Effect: Can print high-definition patterns and support complex designs.

– Advantages: No need to make plates, flexible small batch production.

– Disadvantages: High cost, dark fabrics need to be painted with a white base first.

Expertise in SEWING INDUSTRY-CUSTOM BAG

LOGO & Branding Selection Suggestion.

The selection of the appropriate process requires comprehensive consideration of brand positioning, luggage materials, usage scenarios and budget. It is recommended to communicate with us -professional suppliers and make samples to confirm the effect.

- High-end leather bags: Prefer embossing, laser engraving or metal labels.

- Outdoor sports bags: Embroidery or high wear-resistant silk screen.

- Light luxury brand: Hot stamping/hot silver, drip glue process.

- Environmentally friendly products: Laser engraving (no chemical additives) or recycled materials combined with silk screen.

Durability test: Different processes need to test wear resistance, water resistance, and UV resistance.

– Material adaptability: Nylon fabric is not suitable for high-temperature hot stamping, and genuine leather needs to avoid excessive laser ablation.

– Process cost: Digital direct printing or 3D printing can be selected for small-batch customization, and embossing or silk-screen printing is preferred for large-scale production.

– Design complexity: Avoid embroidery for fine patterns, and water transfer printing is preferred for curved logos.

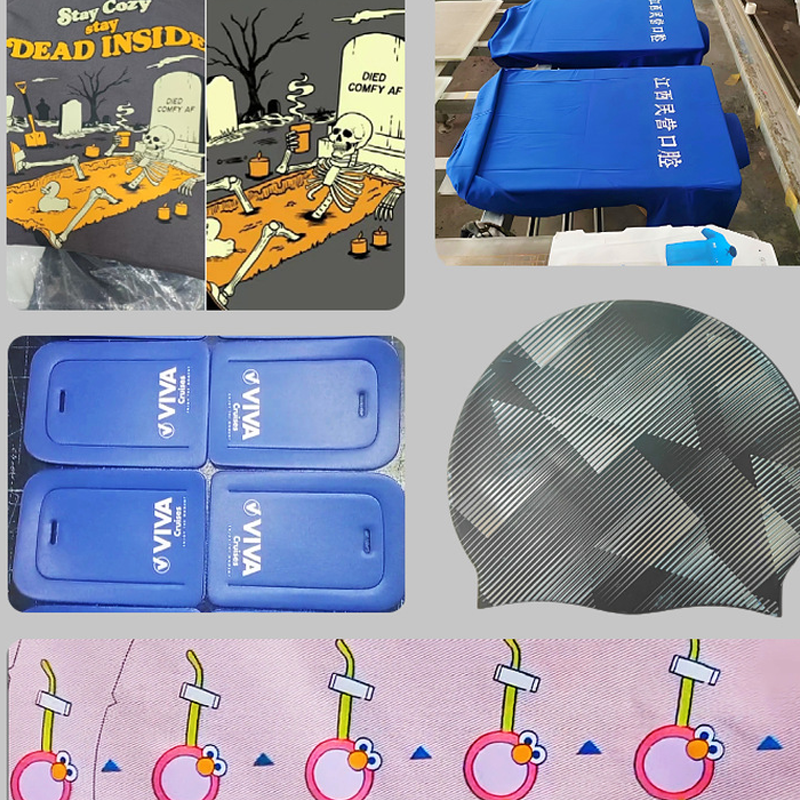

Pictures To Show Manufactory

CHina Manufactory Of Various Bags /Leather goods/Gifts /Promotion Products

Custom Bag We Servey

MANUFACTORY TEAM

There are 200+ workers in factory , they from different departments to provide quality service to your project , QC department , purchasing department , cutting department , sewing department , assembling works-shop , high frequency work-ship , computer sewing workshop ,imprint workshop , pattern office etc. our experienced professionals ensure that quality is reliable from source materials to every stage of the cutting and sewing

SAMPLE ROOM

There are various 1000+ items display in the sample room which is all produce or design by customer or our own designer, applicate in many industries , from pet supplies to sport bags, leather tags , gift bag ,tote , straps etc ,please click for know more. if you have a concept in mind ,custom Bag team of the skilled designer work with you to return the idea into reality . whatever the application , whatever your have sketching ,samples..

WORKSHOP

Expert stitching service ,we still provide Quality craft-ship , 100,000 ft. production facility with over 120 sewing machines and 10 assembly lines ,automated cutting services ,and export supply chain . this allows your project to be produced by skilled team. there are products of 70% need make by hand .with professional and skilled , industrial manufacturing service , full-package ad marketable designs and ideas are available at any scale .

Industry We Serve

China Manufactory Of Various Bags /Leather goods/Gifts /Promotion Products

Custom Bag We Serve

TREND & FASHION

Fashionable and popular industry bag design styles change, from the beginning of the Tote, Boston bag, shoulder bag and other basic styles evolved to today’s cloud bag, dinner bags, cell phone bags, headphone bags and other fashionable elements closely linked to the fashion trend!

OUTDOOR & TRAVEL

Camping bags, Hiking Bag / fanny packs, shoulder bags with environmentally friendly lightweight recyclable material as the main material, waterproof wear-resistant and tear-resistant functional fabrics for the majority of people who love the outdoor service…

SPORT & HEALTH

In office buildings and public places need to be equipped with a medical bag has become a legal security provisions, wear-resistant waterproof fireproof fabric material is mainly used in these industries, lightweight storage can be carried Insulation function backpack ,shoulder Bag ,Stroller bag etc …

INFANT & MOM

Maternal and infant products have very strict requirements on safety and environmental protection, especially the safety of fabrics and accessories. EU standards, CPC, FDA, CE+ EN71+REACH…We will provide corresponding certification according to the requirements of the country and customers.

PROMOTIONAL & GIFT

Promotional gifts are widely used in a wide range of industries, from customized business gifts, stationery, bags to Goods, event supplies, and electronic product peripherals. They are functional, beautiful, inexpensive, and are well-liked by major brands and companies. Gifts can bring brands, help promote products, and increase brand awareness.

HOME & STORAGE

Multi-layer compartments + elastic mesh pockets + independent secret compartments, cosmetics, data cables, and jewelry can be stored in categories, clearly visible, and say goodbye to clutter! Customized storage bags can easily exquisite life,Customized storage bags can easily hold your exquisite life, carry it with you on business trips, and travel experts: passports

PETS & TOYS

“It accompanies you through the four seasons, and you give it the most reassuring embrace.”

Customized pet bags, filled with curiosity and love. Short trips: self-driving tours, camping, give your furry child a mobile nest. Daily outings: vaccinations, pet shops, go anywhere without panic,Social experts: cafes, friends gatherings, cute pets go out and get 100% of the attention …

BUSINESS & GIFT

Take control of the whole situation calmly! custom business bag, hold ambition and support professionalism! Independent computer compartment (adapt to 16-inch notebook) + multi-layer document compartment + hidden card slot, contracts, tablets, business cards are neatly organized. “Your bag carries the weight of decision-making, and we carry your every effort.”

Our Sewing Product Process

Meet Some Of The Team Behind The Scenes

love sewing industry and more 10+ experience on cutting and sewing ,gift and crafts

Renee Gao-

Sale Manager

I have worked in the sewing industry for 10 years,I still love it today. I assist brands in developing new products, material selection, pattern making, testing, and production management. I focus on custom bags well understanding in soft sewing goods on crafts …

John Liu

Sample Maker

I am a hand-maker , i responsible for creating your sample and getting your products ready for production ,many samples are made by hand at beginning for controlling the more lower sample cost.i am delighted when project on line every time, i proud of my job …

Jenny -Production Manager

Production of sewing goods is the integrating management . i need to keep all sewing materials and workforces on schedule before starting production, I am good at managing the workshop and helps keep your projects on time and on budget…

Looking for a reliable parterner for your brand ?

GET IN TOUCH TODAY