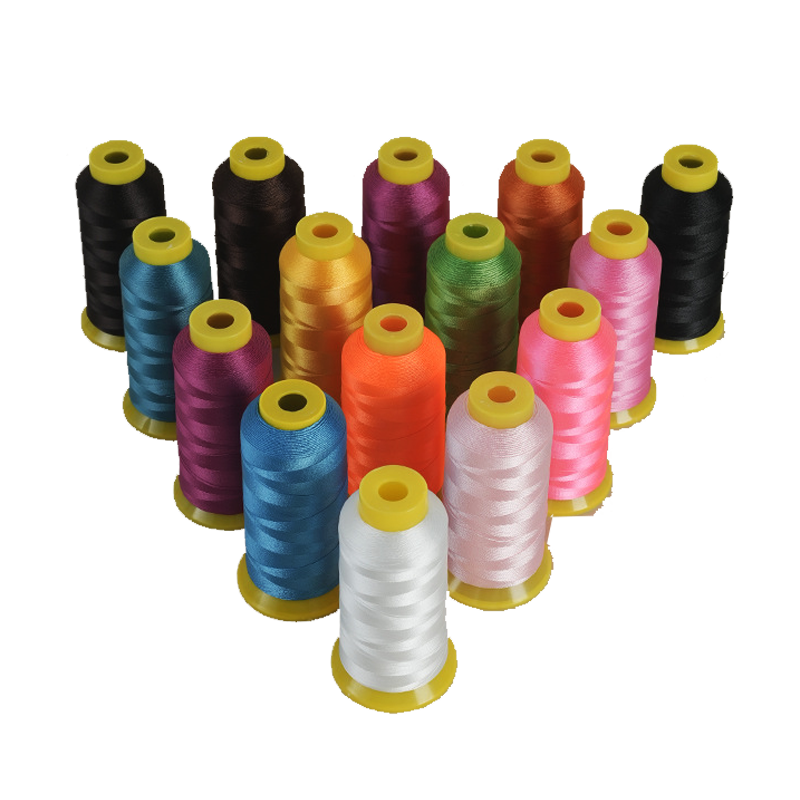

THREAD

When producing bags, the sewing thread used directly affects the strength, durability and aesthetics of the product. Different types of threads need to be selected according to the material of the bag (such as leather, nylon, canvas, etc.) and the process requirements. The following are the types of sewing threads commonly used in bag production and their characteristics:

Polyester thread

-Features:High strength, wear resistance, UV resistance, chemical corrosion resistance, and not easy to shrink.

– High cost performance, it is the most commonly used thread in bag production.

– Applicable scenarios:Suture load-bearing parts such as suitcases, backpacks, and sports bags.

– Suitable for sewing synthetic fiber fabrics such as polyester, nylon, and Oxford cloth.

Nylon Thread

-Features:Good elasticity and extremely high strength (better than polyester), but it is prone to aging and brittleness due to long-term exposure to the sun.

– Smooth surface, suitable for high-speed sewing.

– Applicable scenarios:Mountaineering bags, military bags and other high-strength bags.

– Stitching thick leather or high-density fabrics.

Aramid thread

-Features:Ultra-high strength, high temperature resistance, flame retardant, but expensive.

– Applicable scenarios:Fire bags, military bags and other special-purpose bags.

Avoid mixing materials:

– Nylon thread sewing polyester fabric may cause the thread knot to loosen (due to different shrinkage rates).

– Mildew-proof polyester thread is preferred in humid areas, and cotton thread is avoided

Transparent thread

-Features: Nylon or polyester material, invisible stitching.Applicable scenarios:- Light-colored or transparent fabric bags to avoid color difference problems.

-Gold and silver thread/decorative thread Features:

– Metallic luster, beautiful but low strength.

– Applicable scenarios: Decorative stitching of luxury bags.

Cotton thread

-Features :Naturally soft, environmentally friendly and skin-friendly, but low strength and easy to mold.

– Applicable scenarios:Decorative stitching of canvas bags, cotton and linen bags. Not recommended for load-bearing parts.

-Blended thread Features:Combining the advantages of multiple fibers, such as polyester-cotton thread, which takes into account both strength and softness.Nylon core-spun thread (outer polyester + inner nylon) has a wear-resistant surface and strong internal structure.

High-strength thread

-Features:Multiple strands twisted together, extremely strong tension (such as #40, #60 high-strength polyester thread).Applicable scenarios:Stress-bearing parts of bags (shoulder straps, handles, zipper stitching.

-Wax thread Features:Wax-impregnated surface, waterproof and mildew-proof, reduces sewing friction.Applicable scenarios:– Leather bags (such as handmade leather goods stitching), outdoor waterproof bags.

Special Function Line

-Reflective line,Add reflective material to improve nighttime visibility, used for outdoor backpacks.

-Fireproof line,Flame retardant treatment, suitable for firefighting or industrial bags.

Degradable lineEnvironmentally friendly materials (such as PLA polylactic acid), used for sustainable design of bags.

Thread Number Rule

— The smaller the number, the thicker the thread (such as #20 is thicker than #40, and has higher strength).

– Common thread numbers**:

– #20~#30: stitching heavy parts such as thick leather and bag frames.

– #40~#60: stitching of conventional bag fabrics (nylon, polyester).

– #80~#100: ultra-thin fabrics or fine decorative stitching.

Expertise in SEWING INDUSTRY-CUSTOM BAG

Thread Material Selection Suggestion.

Choosing the right sewing thread can significantly improve the quality of luggage. It is recommended to cooperate with professional thread suppliers and provide sample tests according to actual needs before purchasing in bulk.

1.Suitcase/trolley case:

– Main stitching: #40 high-strength polyester thread (wear-resistant and tensile).

– Zipper stitching: #60 nylon thread(elastic adaptation to zipper expansion).

- Outdoor backpack:

– Stress-bearing part: #30 nylon thread or aramid thread.

– Waterproof treatment: wax thread or polyester thread + waterproof glue coating.

- Leather bag:

– Hand-sewing: 0.8mm~1.2mm wax thread(such as hemp wax thread).

– Machine sewing: #20~#30 polyester bonded thread**.

- Luxury bag:

– Decorative thread: Gold and silver thread or high-strength thread of the same color as the fabric.

– Hidden stitching: Transparent nylon thread.

Six, sewing thread matching points

– Needle and thread matching:

– Thick thread (such as #20) needs to be matched with large needles (such as 18 needles).

– Thin thread (such as #60) is matched with 11~14 needles.

– Color selection:

– General: The thread is the same color as the fabric or one darker color.

– Design sense: Contrast color stitching (such as black bag with white visible thread).

– Test requirements:

– Perform tensile test (such as ASTM D5034 standard) and friction test

Notes

- Avoid mixing materials:

– Nylon thread sewing polyester fabric may cause the thread knot to loosen (due to different shrinkage rates).

- Environmental adaptability:

– Mildew-proof polyester thread is preferred in humid areas, and cotton thread is avoided.

- Equipment compatibility:

– Industrial sewing machines need to use silicone oil-treated thread to reduce thread breakage.

We Build Quality Products We Are custom bag factory We Are Fully Committed to international Manufacturing Standards ISO9001

- Custom Tote Bag Manufacturers-Click For More Information

- Custom Handle Bag Manufacturers-Click For More Information

- Custom Backpack Manufacturers-Click For More Information

- Custom Mummy Bag Manufacturers-Click For More Information

Custom Travel Bag Manufacturers-Click For More Information

Custom Pet Bag Manufacturers-Click For More Information

Custom Promotional Bag -Click For More Information

Custom Cooler Bag Manufacturers-Click For More Information

- Custom Clutch Bag Manufacturers-Click For More Information

- Custom Leather Goods Manufacturers-Click For More Information

Custom Cosmetic Bag Manufacturers-Click For More Information

Pictures To Show Manufactory

CHina Manufactory Of Various Bags /Leather goods/Gifts /Promotion Products

Custom Bag We Servey

MANUFACTORY TEAM

There are 200+ workers in factory , they from different departments to provide quality service to your project , QC department , purchasing department , cutting department , sewing department , assembling works-shop , high frequency work-ship , computer sewing workshop ,imprint workshop , pattern office etc. our experienced professionals ensure that quality is reliable from source materials to every stage of the cutting and sewing

SAMPLE ROOM

There are various 1000+ items display in the sample room which is all produce or design by customer or our own designer, applicate in many industries , from pet supplies to sport bags, leather tags , gift bag ,tote , straps etc ,please click for know more. if you have a concept in mind ,custom Bag team of the skilled designer work with you to return the idea into reality . whatever the application , whatever your have sketching ,samples..

WORKSHOP

Expert stitching service ,we still provide Quality craft-ship , 100,000 ft. production facility with over 120 sewing machines and 10 assembly lines ,automated cutting services ,and export supply chain . this allows your project to be produced by skilled team. there are products of 70% need make by hand .with professional and skilled , industrial manufacturing service , full-package ad marketable designs and ideas are available at any scale .

Our Sewing Product Process

Meet Some Of The Team Behind The Scenes

love sewing industry and more 10+ experience on cutting and sewing ,gift and crafts

Renee Gao-

Sale Manager

I have worked in the sewing industry for 10 years,I still love it today. I assist brands in developing new products, material selection, pattern making, testing, and production management. I focus on custom bags well understanding in soft sewing goods on crafts …

John Liu

Sample Maker

I am a hand-maker , i responsible for creating your sample and getting your products ready for production ,many samples are made by hand at beginning for controlling the more lower sample cost.i am delighted when project on line every time, i proud of my job …

Jenny -Production Manager

Production of sewing goods is the integrating management . i need to keep all sewing materials and workforces on schedule before starting production, I am good at managing the workshop and helps keep your projects on time and on budget…

Looking for a reliable parterner for your brand ?

GET IN TOUCH TODAY